Infrastructure

Our Facilities

Welcome to our state-of-the-art facility at TechEra, strategically designed for precision and efficiency. Spanning an expansive 78,000 sq. ft., our facility houses two specialized plants.

Manufacturing Plant 1

Equipped with cutting-edge machinery and operated by skilled professionals, our manufacturing plant is the heart of innovation. Here, we craft intricate components with utmost precision, ensuring the highest standards in every product.

From raw materials to the finished product, our facility is designed to streamline the entire production process. At TechEra, we take pride in our commitment to quality, innovation, and operational excellence within this expansive space.

Manufacturing and Quality Control

- Facility Area: 78,000 sq. ft. / 7000 sq mtr.

- Manufacturing and Quality Control: 20,000 sq. ft.

- Assembly and Integration: 18,000 sq. ft.

Our Machinery

FERMAT 5-Axis Horizontal Boring Machine

Machine Specification

- X Axis : 5000 mm

- Y Axis : 3000 mm

- Z Axis : 2500 mm

- Table size: 3000 mm x 2000 mm

DMG DMU 65 Mono Block

Machine Specification

Linear axes (X/Y/Z)

- Feed: 40,000 mm/min

- Rapid traverse: 40 m/min

- Acceleration: 6 m/s'

Main drive (Standard)

- Rotational speed: 15000 rpm

- Spindle taper: SK 40 DIN 69871

- Power: 46 kw

- Machine accuracy in X, Y & Z axis: <= 0.006 mm

Swivelling Rotary table (Mill-turn with C-axis speed)

- Maximum load (single drive/twin drive): 600 kg

- Maximum work piece dimensions: 840 mm

- Maximum work piece height: 500 mm

Our 3-Axis and Conventional Manufacturing Setup

Micromatic Cylindrical Grinding

Jyoti VMC 1060

Jyoti 1060

BFW Chakra

Jyoti PX 40

SIP Jig Boring

Alex Surface Grinding

Jyoti CNC Turning DX 200

BFW Vajra Machine

Machine Specification

- X: 2000 mm

- Y: 800 mm

- Z: 800 mm

- RPM: 6000

TechEra Quality Control

At TechEra, our Quality Control setup is designed to meet the rigorous demands of the aerospace industry and tooling manufacturing. Our facility features a Fixed Bed CMM, a state-of-the-art FARO laser tracker, and 2 portable CMMs from FARO for precise 3D measurements. Additionally, we utilize a hardness tester, surface finish measurement equipment and Trimos for comprehensive quality assessments. This advanced array of equipment ensures that we maintain the highest standards of accuracy and reliability in every project.

Accurate Fixed Bed CMM

Machine Specification

- Accurate CMM: Megha

- Accuracy: 0.002 mm ( Repeatability)

Range

- X: 1200 mm

- Y: 2000 mm

- Z: 1000 mm

FARO Laser Tracker

Machine Specification

- Faro laser Tracker Vantage E

- Range: 80 mtr

- Accuracy : 2 mtr - 16 mtr mm-0.8 mm/m

- 6 Degree Freedom

FARO Portable CMM

Machine Specification

Machine 1

- Faro Arm Quantum E

- Range: 3.5 mtr

- Accuracy: 0.075 mm

Machine 2

- Faro Arm Quantum M

- Range: 2.5 mtr

- Accuracy: 0.075 mm

Our Machinery

Fabrication & Quality Setup

Quality norms to meet the desired results and to follow the below documentation process:

- Assembly Inspection & Jig Setting reports

- Welding reports

- Calibration reports etc.

- Raw Material Inspection report – NABL approved

- Part Inspection reports

- CMM reports / Tracker reports

ACCURATE Fixed Bed CMM

Machine Specification

Model: Mega

Measuring range (mm)

- X axis: Mega: 1200, Mega AL: 1500

- Y axis: Mega: 1500-2000, Mega AL: 2000-2500

- Z axis: Mega: 1000, Mega AL: 1200

Mode of operation

- Motorised / CNC

Clearance under bridge (mm)

- Mega: 950, Mega AL: 1600

Resolution (in µm)

- 0.1 / 0.5

Max. Workpiece weight (kg)

- Mega: 1000, Mega AL: 4000

Accuracy MPEE (as per ISO 10360- 2 with TP 200 in µm)

- Mega: 1.9 + L / 350, Mega AL: 2.2 + L / 350

Guidance

- Air bearings on all axes

Linear Velocity

- Mega: 350 mm/s, Mega AL: 300 mm/s

Volumetric Velocity (3D)

- Mega: 600 mm/s, Mega AL: 520 mm/s

Measuring table (Material)

- Granite

Probing option

- TP 20, TQ200,SP 25M, Revo, Laser scanner

Probe heads

- MH8, MIH, PH10, PH20, SP80

ACCURATE Fixed Bed CMM

Machine Specification

Model: Mega

Measuring range (mm)

- X axis: Mega: 1200, Mega AL: 1500

- Y axis: Mega: 1500-2000, Mega AL: 2000-2500

- Z axis: Mega: 1000, Mega AL: 1200

Mode of operation

- Motorised / CNC

Clearance under bridge (mm)

- Mega: 950, Mega AL: 1600

Resolution (in µm)

- 0.1 / 0.5

Max. Workpiece weight (kg)

- Mega: 1000, Mega AL: 4000

Accuracy MPEE (as per ISO 10360- 2 with TP 200 in µm)

- Mega: 1.9 + L / 350, Mega AL: 2.2 + L / 350

Guidance

- Air bearings on all axes

Linear Velocity

- Mega: 350 mm/s, Mega AL: 300 mm/s

Volumetric Velocity (3D)

- Mega: 600 mm/s, Mega AL: 520 mm/s

Measuring table (Material)

- Granite

Probing option

- TP 20, TQ200,SP 25M, Revo, Laser scanner

Probe heads

- MH8, MIH, PH10, PH20, SP80

Plant 2

Assembly and Integration Plant

Dedicated to the seamless assembly and integration of our technological solutions, this plant is a hub of collaboration and efficiency. Our skilled team meticulously combines components to create robust systems, ready to meet the demands of our dynamic industries.

At TechEra, our primary aim is to leverage our manufacturing competency and advanced infrastructure to redefine precision manufacturing. We are committed to setting industry benchmarks by seamlessly integrating cutting-edge technology with our manufacturing processes.

Manufacturing Setup

FERMAT 5 Axis

DMG MORI DMU65 5 Axis

VMC 1060 : 1nos

CNC DX200 : 2nos

SIP JIG Boaring

BFW Vajra 1800mm

VMC PX40 : 2nos

Surface Grinding

Fabrication & Quality Setup

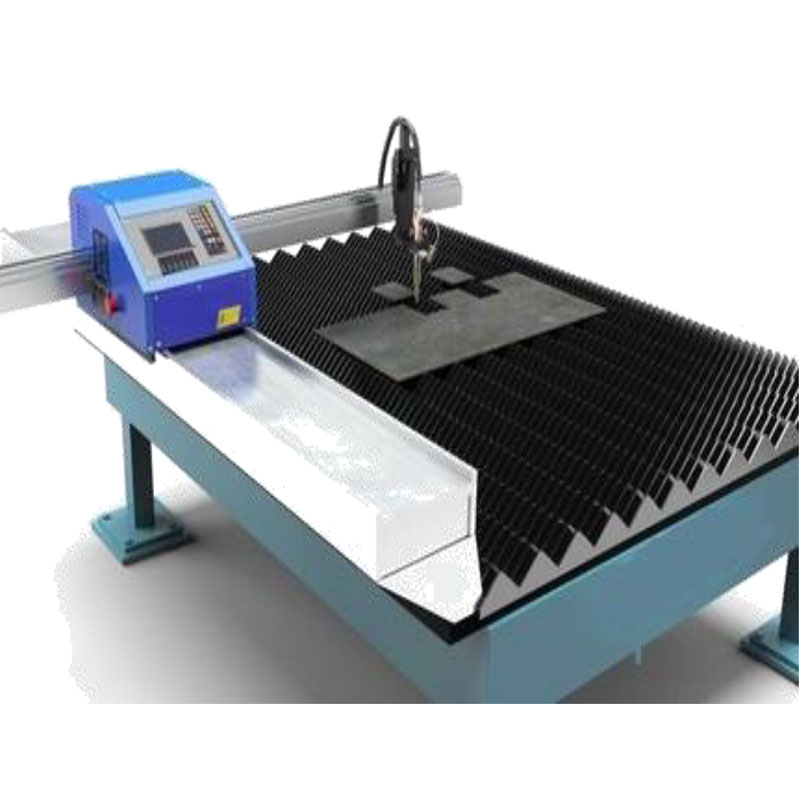

CNC Profile Cutting Machine

Faro Arm 3.5M

Faro Arm 2.5M

Trimos Digital height Gauge

FARO Laser Tracker

Accurate CMM Mega

Quality norms to meet the desired results and to follow the below documentation process:

- Raw Material Inspection report – NABL approved

- Part Inspection reports

- CMM reports / Tracker reports

- Assembly Inspection & Jig Setting reports

- Welding reports

- Calibration reports etc.

We are well equipped with Welding and Fabrication setup

- CNC Cutting Machine

- Fronius Welding Machines

- Base Structure 5Mtrs X 2.5Mtrs for critical fabrication

- Certified Welders AWS

- Third Party AWS Certified Welding Inspection

- Level II Certified Tester for NDT Testing